Wind Turbine Measurement

Wind Turbines provide their own unique challenges when it comes to performing measurements; the height, the need for specialist trained personnel, danger from high voltages and moving plant are just some of the obstacles faced when planning measurements on a wind turbine. This is made all the more difficult when measurements are required on a live, operational asset where health and safety must come first, requiring personnel not to ascend the tower and remain on the ground. As turbines become ever taller, with many of the newest turbine’s hub heights being well over 100m, how can these measurements be undertaken without compromising accuracy and safety?

Xi’s Method for On-Tower Measurement

Safe -No Operatives in an operational asset

Expandable -The system works on any scale of wind turbine: 140m+ tower heights

Comprehensive – Xi’s system allows high resolution measurements to be made simultaneously over the whole system

Flexible – An adaptable measurement system that allows any configuration of sensors to be logged

Xi’s team of engineers are certified for both working at height and working offshore and have successfully performed vibration measurements safely on a wide range of wind turbines, from small systems where the only access to the nacelle is external ladder or by lowering the tower, to the world’s largest wind turbines -140m tall hybrid towers. The techniques and processes deployed have been developed and refined by Xi engineers by working on real systems. Each measurement is dependent on the system and requirements of the project, but in all cases the process allows measurements to be taken quickly, efficiently and above all safely. Sensors and cables are deployed on the tower and nacelle whilst the turbine is shutdown. Then the turbine is started and measurements take place with engineers remaining safely on the ground.

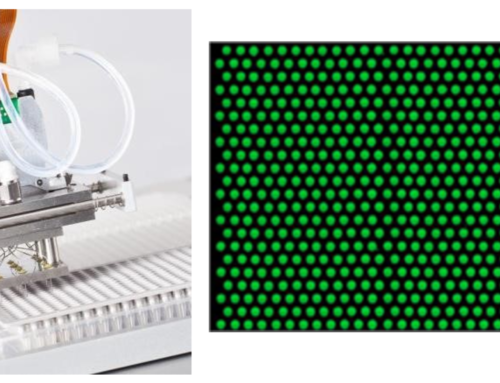

Sensor Deployment

The process begins by installing a cable network from the base of the turbine to the nacelle. The main control hub (or node) is situated at the base of the tower where recordings can be made safely – away from moving parts. Intermediate local DAQ nodes are then located throughout the tower allowing sensors to be deployed at all levels of the wind turbine system providing simultaneous measurement at high data acquisition speeds. With sensors in position engineers can then descend the tower and run the wind turbine through a variety of operations whilst synchronous measurements of the turbine dynamics are made. The system is completely expandable allowing multiple local measurement nodes over many hundreds of meters, the system can be used for any sensor type and allows high sampling speeds of up to 10kHz.