The Challenge: Keeping High-End Audio Electronics Cool

Linn, a world leader in high-performance audio systems, needed high-end electronics cooling system optimisation to maintain consistent temperatures within their speakers and amplifiers, ensuring distortion-free sound and peak performance. By leveraging advanced simulations, Linn could accelerate this optimisation process and improve their cooling system design.

Our Solution: Fin Design Optimisation Using Simulation

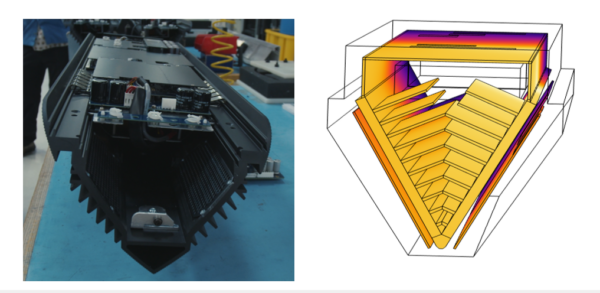

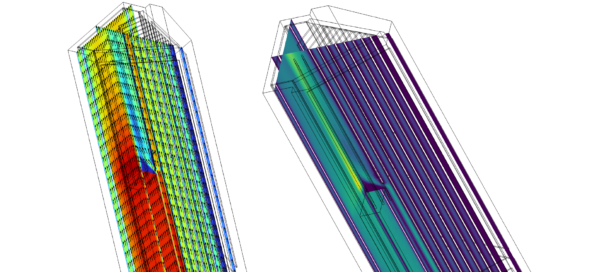

Unlike most electronics, which use noisy fans for cooling, Linn opts for silent, passive cooling systems. These systems operate similarly to a chimney, using aluminium fins to transfer heat away from the amplifiers through natural air circulation. The effectiveness of these passive cooling systems depends on the precise shape of the aluminium fins.

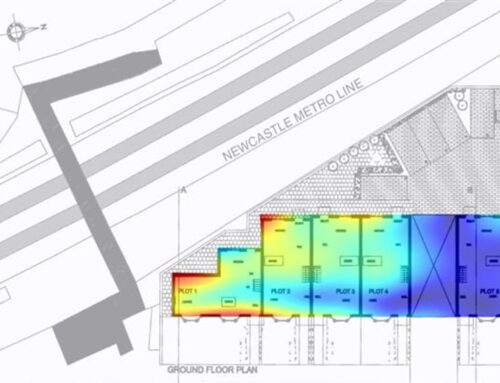

Traditionally, engineers would create multiple fin designs, machine prototypes, and conduct physical tests, a process that was both time-consuming and expensive. To streamline this, Linn leveraged Xi Engineering Consultants’ expertise in Multiphysics simulations to model complex factors like airflow, temperature, fluid viscosity, and heat transfer. This allowed Linn to avoid the costly cycle of physical prototyping and optimise their cooling designs through simulation.

Client Benefits: Rapid Design Optimisation with Simulations

Using advanced simulations, Linn was able to rapidly test multiple configurations of their cooling system and optimise designs without needing to build physical prototypes. The high-end electronics cooling system optimisation ensured Linn’s products maintained superior performance while reducing costs and development time. The iterative simulation process enabled quick assessments of design changes, saving time and resources while allowing Linn engineers to focus on performance and aesthetics.

Additionally, simulation provided insights into internal thermal structures, which are difficult or impossible to measure in physical tests. This additional data informed better design decisions, further improving product performance.

Key Expertise Used:

- Computational Fluid Dynamics (CFD)

- Thermal Modelling

- Multiphysics Simulations with COMSOL

- Design Optimisation

- Cloud Computing

A Shared Commitment to Excellence

Both Xi Engineering Consultants and Linn are dedicated to engineering excellence and innovation. This partnership is built on a foundation of shared values, pushing the boundaries of technology in the audio industry. Xi Engineering Consultants specialise in Simulation, Data Analysis, Advanced Measurements, Digital Twins, and Machine Learning. Our expertise accelerates product development, optimises performance, and ensures engineering excellence across sectors.

What Linn Says About the Collaboration

“Simulation allows us to rapidly progress through the development process, giving us more time to work on the performance of our products,” says Phil Budd, Mechanical & Acoustics Team Leader at Linn. This collaboration demonstrates how advanced simulation techniques can accelerate product development while maintaining Linn’s reputation for unparalleled audio quality and reliability.

“Both Linn and Xi Engineering Consultants have a similar engineering ethos: it’s about pursuing excellence,” adds Phil Budd.

Collaboration Story

Learn more about this project and the collaboration between Linn and Xi Engineering Consultants in our video: