Innovating faster with digital twin technology

Innovation has always involved trial, error and risk. Today, the teams that move quickest are those who can experiment in the virtual world before they cut metal, pour concrete or release code.

Digital twin technology gives you that advantage. At Xi Engineering Consultants, we build digital twins that connect high fidelity multiphysics models with live or periodic data, so you can test ideas faster, de risk decisions and keep improving products and assets after they go into service.

Why digital twins matter for innovation

Bringing a new product or system to market still carries familiar pressures:

- Prototypes and physical tests are expensive and time consuming

- Late design changes can ripple through tooling, supply chains and approvals

- Once assets are in the field, insight into real performance can be limited

Digital twin technology tackles these head on.

By linking a virtual model to data from the real world, you can:

- Explore more design options without building a physical prototype each time

- See how products and assets behave in real conditions, not just in the lab

- Spot emerging issues earlier and act before small problems become failures

- Feed operational insight back into the next generation of designs.

This is why sectors from motorsport and automotive to infrastructure, manufacturing and healthcare are investing heavily in digital twins.

What a digital twin actually is

A digital twin is more than a static CAD model or one off simulation.

At Xi, we define a digital twin as:

A multiphysics model that is tethered to a real product, asset or process using data transfer at an appropriate update rate.

Three elements matter:

- A robust virtual model

A simulation that captures the key physics of your system – structural, acoustic, thermal, electromagnetic, fluid or a combination. - A data connection

Sensor or system data that is streamed or transferred to update the model periodically or in real time. - A clear purpose

A defined set of questions the twin is there to answer – for example performance under different conditions, remaining life, or the impact of design changes.

Digital twins sit on a spectrum. Some are updated every few seconds, others once a day or once per operating cycle. The right approach depends on what you need to monitor and decide.

From one off tests to continuous insight

Historically, many complex products were only examined in detail twice in their life:

- At development and type testing

- At the end of life teardown

Everything in between was largely inferred from occasional inspections and maintenance records.

With connected sensors and modern data infrastructure, that has changed. Today it is practical to:

- Monitor critical parameters in service, from vibration and temperature to load and flow

- Combine that data with a calibrated model to estimate stresses, damage and remaining life

- Run what if scenarios – for example how output, settings or environment will affect performance and risk

In sectors such as aviation and power generation, digital twins are already used to optimise maintenance, reduce downtime and improve safety for assets like jet engines, turbines and locomotives.

The same principles can apply to many other systems, from factory equipment and consumer products to infrastructure and cities.

Getting to market faster with virtual prototypes

For new products and systems, digital twins start life as virtual prototypes.

By building and validating a high quality model early, you can:

- Replace some rounds of physical prototyping with virtual experiments

- Test performance across a wider range of scenarios than would be practical in the lab

- Explore sensitivities to different design variables before you lock in geometry and materials

- Optimise control strategies and operating envelopes ahead of deployment

Once the physical product exists, the same model can be:

- Updated with measurement data to improve accuracy

- Simplified into a reduced order model suitable for real time or near real time use

- Connected to live data streams to become a full digital twin

The result is a smoother transition from R and D into operations, with fewer surprises along the way.

When a digital twin is worth the investment

Not every system needs a digital twin. In our experience, it becomes compelling when:

- Your product or asset has many interacting variables that are costly to explore physically

- You face high consequences for failure – safety, regulatory, financial or reputational

- You plan multiple generations of a product and want to build structured learning into each cycle

- You operate fleets of similar assets and need to understand both typical and outlier behaviour

Examples include:

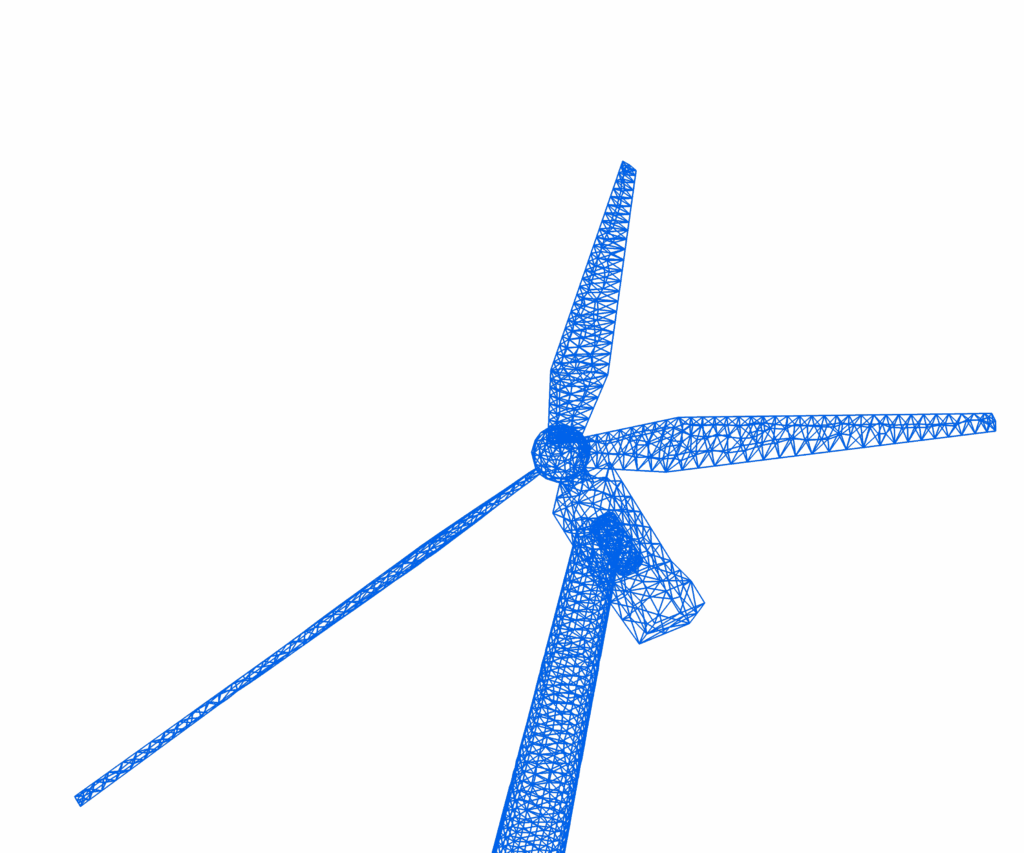

- Wind turbines and other renewable energy assets

- High value rotating equipment and drives

- Vehicles and transport infrastructure

- Complex consumer products where over the air updates are possible

If you recognise your context in this list, the question is less whether to use a digital twin and more how to design one that is proportionate and useful.

How Xi builds and deploys digital twins

Xi Engineering Consultants brings together simulation, measurement, machine learning and software deployment to create digital twins that engineers actually use.

A typical engagement follows three stages.

- Build the model

- Capture key physics using multiphysics simulation

- Calibrate the model with lab or field measurement data

- Validate against known operating scenarios and test cases

- Understand sensitivities

- Explore how changes in design, environment or operating conditions affect outputs

- Identify which variables are most important to measure or control

- Simplify the model where appropriate for efficient runtime

- Deploy the digital twin

- Connect the model to data sources at the right update rate

- Provide a clear interface for engineers and decision makers

- Iterate as new data arrives, improving accuracy and usefulness over time

In many projects we also create online or cloud hosted versions of models, so your wider team can access insight without needing specialist simulation software.

We can engage on focused studies around a specific problem or as an ongoing partner across generations of a product line.