Tonal noise produced by wind turbines is a serious and often complex issue which can be particularly vexatious to residential communities. Tonal noise emissions are subject to strong regulatory penalties resulting in; curtailment, loss of yield and even the complete decommissioning of wind turbines. Xi Engineering Consultants have been solving tonal noise issues in wind turbines for over ten years for clients throughout the United Kingdom, Europe, North America and Asia.

Noise from wind turbines has two main sources; aerodynamic noise – resulting from the blades, and mechanical noise – associated with components in the drive train. Mechanical noise is produced by the rotating machinery within the nacelle of the turbine such as the gearbox or the generator. These systems produce discrete vibrations at specific frequencies. Problematic or excessive noise occurs when these vibrations interact with a large radiating surface such as the blades or tower walls – much like the cone of a loudspeaker system.

Xi’s process follows a system of BEP (Best Engineering Practice). This allows efficient and cost-effective arrival at solutions and provides an accountable process to regulators.

Stage 1 – Measure

Xi’s established process begins with a detailed vibration and acoustic survey of the tone emitting turbine by our working at height accredited engineers. This typically takes 1 to 3 days depending on the scale of the turbine; be it a tip height of 20m or 200m. Xi’s survey process is accurate and safe in accordance with the Institute of Acoustics Good Practice Guide. If required, Xi can carry out surveys following either IEC 61400-11 Edition 3 and/or ETSU R97.

The measurements characterise the precise frequencies associated with the problematic noise, which can then be linked through all the measurement points allowing the vibration source, pathway, and radiating surface to be established.

Stage 2 – Modelling & Simulation

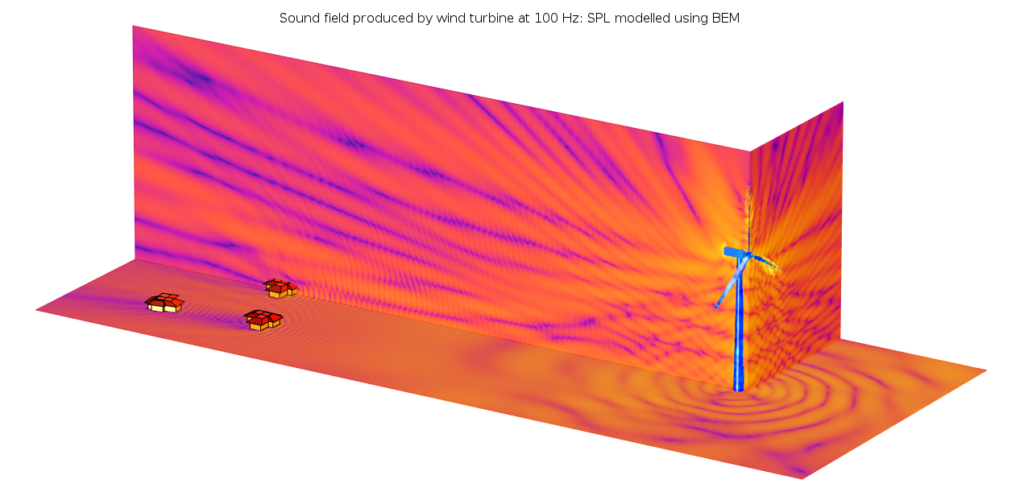

Following measurements, we establish the precise dynamics of the tonal noise by simulating the system using COMSOL Multiphysics with our in-house structural-acoustic modelling techniques and utilising COMSOL’s powerful BEM (Boundary Element Modelling) solvers. The model is constructed using engineering drawings and validated using data from the vibration and acoustic survey. Once completed the model can be used to show an acoustic contribution from the various components of the wind turbine, for example, how much noise is transmitted from the nacelle versus from tower walls. This allows for an informed and targeted approach when designing acoustic solutions. Once validated, the model then acts as a virtual test-bed to determine the best solution for the turbine and optimise the solution.

Stage 3 – Solution

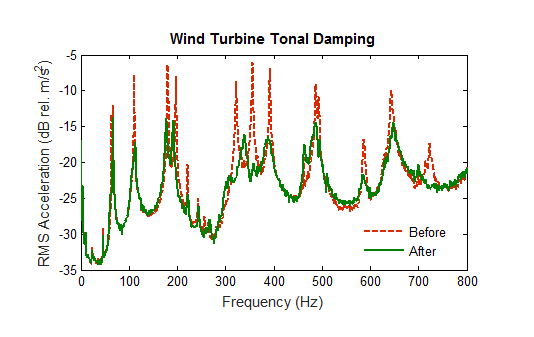

An optimal solution for one wind turbine may not be the most effective for another. Xi’s well established 3 stage process provides fundamental knowledge for specifying an effective and efficient tailored solution. This solution is then optimised, refined and tested in a virtual environment using COMSOL Multiphysics, allowing a full cost-benefit analysis for all options. Xi’s success in developing noise mitigation has seen us develop a range of tonal noise mitigation techniques, from increasing the damping of the turbine tower, stopping frequency matching between components and isolation of the nacelle from the tower. Our solutions have proved extremely effective at frequencies below 800 Hz, especially at the traditionally challenging low frequencies, providing significant tonal reductions, of up to 15 dB.

Why choose Xi

We have extensive experience in providing design, noise and vibration solutions for all scales of wind turbines and work with a variety of stakeholders in the sector, including developers, manufacturers, regulatory bodies and residential communities. Using sophisticated analysis and modelling techniques, we are able to assess wind turbines in order to improve designs and reduce unwanted noise and vibration problems including:

- Wind turbine acoustic measurement and assessment in accordance with IEC 61400-11 Edition 3 and ETSU R97 and the Institute of Acoustics Good Practice Guide.

- Wind turbine noise damping.

- Tonal and broadband noise mitigation solutions that reduce the acoustic impact of wind turbines on neighbouring communities.

- Drivetrain design support including finite element analysis of fatigue risk.

- Vibration measurement to support and supplement Condition Monitoring Systems (CMS)

- Advanced measurement techniques such as Torsional Vibration Analysis of rotating drive shafts

- Lifetime extension analysis based on the fatigue life of towers and foundations.

- Expert witness testimony related to noise and vibration from wind turbines at public inquiries.

- Seismic ground vibration measurements and modelling to determine the impact of wind turbine vibrations on ultra-sensitive scientific equipment such as seismic stations used for nuclear testing monitoring, gravitational wave detectors and astronomical observatories

For more information please don’t hesitate to contact our team. We are always happy to talk about exciting new projects and find ways to unlock their true potentials.